limited production :: hand crafted :: high performance :: rechargeable :: premium flashlights

This is my blog about creating a startup LED flashlight business. I'm a designer, fabricator, and strategist and I'm passionate about making ideas real. I believe that products are about people, that they should be built to last, deliver real value, and that we need to do a better job than we have in the recent past.

Most of my career has been contract or freelance work and I've crafted products and strategies for both big international companies and startups. I also used to work in the "industry" fabricating special effects for film and TV, along with the occasional hot rod. Bottom line, I love making things.

I'm starting this blog so you can follow along, from day one, and see what it's like to start a business, or fail in the process. Only time will tell, but I hope you find this interesting enough to stay tuned, comment, link, like, tweet, and (most importantly) participate in turning this idea into something tangible and valuable.

For a good place to get started with general info about who, what, why, etc., check out the "Stickies" on the left side of the page. Thanks for stopping by and please don't hesitate to ask questions and get involved!

Please sign up for my email list to get updates and notifications for contests and giveaways!

Saturday, December 1, 2012

Saturday, November 17, 2012

When in doubt, MacGyver it

|

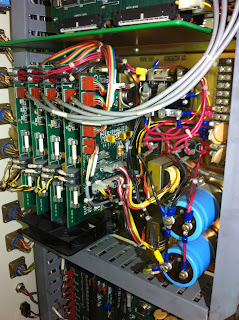

| Yeeep, right in between those drive cards. Oh and don't touch the capacitors. |

|

| It ain't purdy but it worked |

Saturday, July 28, 2012

Joby, meet Alpha. Alpha, meet Joby.

The cool thing about this particular tripod is the little red feet are magnetic, increasing the versatility even more. It's amazing for automotive work.

|

| Time to start putting light where I need it |

Friday, March 9, 2012

Laser cutting LED thermal pads (Epilog Helix)

Friday, June 3, 2011

Odd Job: Mission Motors

|

| parts and prints, always satisfying! |

Friday, May 20, 2011

"I Recommend": G-Wizard Calculator (for machinists)

Okay, I have a notebook with a list of things I think are AWESOME. Most of the time I forget to write things down on that list, but I have a few and thought I'd start sharing them on my blog. These things aren't necessarily flashlight related, but if they apply to you, they will change your life. Bold claim eh? But I'm serious. I'm going to call this segment, "I Recommend..." I can't think of a better product to start with that Bob Warfield's G-Wizard machining calculator. It's like having a master machinist in your back pocket. Normally that would be really uncomfortable...but not with G-Wizard. You should really stop reading this and download the trial from this link right: here.

|

| A perfect example of what the internet should be used for |

Wednesday, March 23, 2011

Haas VF-1 milling a custom flashlight head

Tuesday, February 8, 2011

Haas VF-1 machining tail cap & PCB sleeve (video)

Sunday, February 6, 2011

Prototype production run: update

|

| Flashlight bodies hot off the CNC |

Wednesday, February 2, 2011

Prototype production run is under way!

I haven't picked the testers yet but I'll make an announcement about the same time I complete final assembly of the lights, so stay tuned!

(if you want to get the chance to do cool things like test future designs, be sure and sign up for my email list!)

Anyway, back to nitty gritty. My saw stop worked great and I spent time cutting stock to length while the machine was running parts. I also have to deburr the edge on every part (one end) so that there isn't any interference when clamping the parts in the vise. We need everything to be nice and straight.

|

| Chicago Pneumatic right angle die grinder with an 80 grit abrasive disk and a bunch of parts waiting to be deburred. |

Thursday, January 27, 2011

DtD Update: Soft jaws are finished!

Tuesday, January 25, 2011

DtD Update: machining soft jaws

I had to have some bearings replaced on my mill before I could get to making actual parts. That was finished last week and I've been doing the last of the programming. So far I have about 70 separate programs to make this little light. That means there are 70 "operations"...not including the manual operations. For example: cutting all of the stock to length, sanding down the edges so they are smooth and even, etc. More on that in a future post. Suffice to say, there is a lot of work to do outside of the actual machining. Most of it is manual, and this is the kind of labor that kills product margins.

|

| Soft jaws before machining |

Thursday, January 20, 2011

It's alive! CNC test program (video)

As you know I've been programming like crazy. This video is a test program for the machining of the flashlight body. Two parts are held in the vice at a time. The one on the left is "tail up" and the one on the right is "head up." In other words the tailcap will screw into the part on the left and the head will screw onto the part at the right. After the tail gets machined, the same part is flipped upside down and transferred to the right hand position. Confusing enough?

These parts are only 2 inches tall. The actual flashlight body is 4 inches tall. I'm running these "short" test parts to work out any bugs in the programming without wasting a lot of material. You will notice the machine spindle starts and stops and the coolant goes on and off more than it should. That's because each operation is a separate program and I'm using a master program to call them all as subroutines. Don't worry if that doesn't make sense. That's what the "machining content" warning was all about :) Eventually I'll delete the M09 and M05 codes from the individual programs and that will prevent all the erroneous starts and stops.

So, machine tool geeks...enjoy in HD! That's you Bishop. Oh, and for you people in the real world, here in Silicon Valley "geek" is a flattering term :)