- Post a question in the "questions" section.

- If it's a good enough question I'll turn it into a stand-alone blog post.

- Once I get ten questions that turn into blog posts, I'll randomly choose one of those questions (and its author) out of a hat and they will get a free flashlight + charger + battery. I haven't set pricing yet but you can expect the retail price to be north of $200 bucks.

- This offer will be open for 30 days and will close on March 1, 2011.

- If I don't get 10 post-ables in 30 days, then...I'll re-think this whole thing.

limited production :: hand crafted :: high performance :: rechargeable :: premium flashlights

This is my blog about creating a startup LED flashlight business. I'm a designer, fabricator, and strategist and I'm passionate about making ideas real. I believe that products are about people, that they should be built to last, deliver real value, and that we need to do a better job than we have in the recent past.

Most of my career has been contract or freelance work and I've crafted products and strategies for both big international companies and startups. I also used to work in the "industry" fabricating special effects for film and TV, along with the occasional hot rod. Bottom line, I love making things.

I'm starting this blog so you can follow along, from day one, and see what it's like to start a business, or fail in the process. Only time will tell, but I hope you find this interesting enough to stay tuned, comment, link, like, tweet, and (most importantly) participate in turning this idea into something tangible and valuable.

For a good place to get started with general info about who, what, why, etc., check out the "Stickies" on the left side of the page. Thanks for stopping by and please don't hesitate to ask questions and get involved!

Please sign up for my email list to get updates and notifications for contests and giveaways!

Sunday, January 30, 2011

Ask a question, get an answer!

Friday, January 28, 2011

Tools for tools: Making a saw stop

One of the most common uses for tools, is making other tools. At least that's the joke among machinists...we don't actually make stuff, we just make tools. I'm not sure the previous was a complete sentence, but I recently had the need to up the ante on my efficiency. Each light has four main components that need to be machined. So, if I am making a batch of 20 lights, that makes 80 pieces of stock that I need to cut off from 10-12 foot bars. Kind of a pain, and 20 is a pretty small number. Time to make a depth stop for my chop saw.

|

| The DeWalt Multi-Cutter is a low RPM chop saw designed specifically for metal cutting. |

Thursday, January 27, 2011

DtD Update: Soft jaws are finished!

Wednesday, January 26, 2011

Like my glasses?

I do some consulting work for Skip. I designed the polarizing attachment for his tool that allows the laser spot to be "focused" into a much smaller dot. His tools are used for setting up and aligning CNC and manual machine tools. If you are a machinist you should check out his site! I use one (well, several) on both my manual and CNC mill. It can turn a five minute setup routine into a 30 second setup routine

He was tracking down some new line generating lenses and I was taking up the valuable time of many companies that I will never buy anything from...but they make such cool stuff! Yes, I'm a tech geek if that isn't already painfully obvious. You should have seen the mini-displays: 1280x960 pixels in a package less than an inch square! Not cheap.

Tuesday, January 25, 2011

DtD Update: machining soft jaws

I had to have some bearings replaced on my mill before I could get to making actual parts. That was finished last week and I've been doing the last of the programming. So far I have about 70 separate programs to make this little light. That means there are 70 "operations"...not including the manual operations. For example: cutting all of the stock to length, sanding down the edges so they are smooth and even, etc. More on that in a future post. Suffice to say, there is a lot of work to do outside of the actual machining. Most of it is manual, and this is the kind of labor that kills product margins.

|

| Soft jaws before machining |

Monday, January 24, 2011

HELP: Getting connected to Facebook?!

Don't get ahead of yourself. YES I already have a Facebook page. My question is slightly more sophisticated than "how do I create an account"...slightly.

Something like 500 million users and counting? That's a pretty good potential customer pool. For starters, they all use the internet and when my first production run goes up for sale it will be online. Nice, my first layer of segmentation. Anyway, my primary question is about "step 2" Facebook connectedness.

Saturday, January 22, 2011

What you should know about batteries

|

| If it doesn't say AW then don't put it in your light. |

Friday, January 21, 2011

More prototype images

Three of the lights are all aluminum and three have brass heads. The brass ads a lot of weight, expense, and steam-punk factor. Anyone like the brass? In practice, people fall into two camps:

- The brass makes it way too heavy.

- The brass gives it a nice solid weight.

|

| The surface of these lights are all in an unfinished state, straight off the lathe. |

Thursday, January 20, 2011

It's alive! CNC test program (video)

As you know I've been programming like crazy. This video is a test program for the machining of the flashlight body. Two parts are held in the vice at a time. The one on the left is "tail up" and the one on the right is "head up." In other words the tailcap will screw into the part on the left and the head will screw onto the part at the right. After the tail gets machined, the same part is flipped upside down and transferred to the right hand position. Confusing enough?

These parts are only 2 inches tall. The actual flashlight body is 4 inches tall. I'm running these "short" test parts to work out any bugs in the programming without wasting a lot of material. You will notice the machine spindle starts and stops and the coolant goes on and off more than it should. That's because each operation is a separate program and I'm using a master program to call them all as subroutines. Don't worry if that doesn't make sense. That's what the "machining content" warning was all about :) Eventually I'll delete the M09 and M05 codes from the individual programs and that will prevent all the erroneous starts and stops.

So, machine tool geeks...enjoy in HD! That's you Bishop. Oh, and for you people in the real world, here in Silicon Valley "geek" is a flattering term :)

Monday, January 17, 2011

Can't see in the dark? Push this button. (beam shots)

- Lithium Ion rechargeable batteries

- Massive power

- Pocket sized (1.2" x 5.5")

- Looks awesome

- You can't just go buy one in a store

- Will impress your friends

- Custom made, by me

The black light is a "high powered" dive light that uses 6 C cell batteries.

The green light is a production light from Icon. It's a LED powerd by 2 AA batteries. This light is typical of "super bright LED lights" you will find in retail stores.

The three lights on the right are my prototype custom built lights. They use a single lithium ion rechargable battery. Each one has the same LED but different types of optics, which accounts for the different shape beams in the following photos.

Beam shots are after the jump so "read more!"

Saturday, January 15, 2011

POLL: Is packaging important?

So here is something that I've been wrestling with from a business and product standpoint. I've heard a fair number of people say..."wow this would be great with a really nice box or something." This of course makes me think of Apple and the high praise for their packaging. Here is a photo in case you don't live in Silicon Valley and weren't issued an iSomething when you moved here.

|

| Image courtesy of Apple Insider |

Should my premium flashlights come with premium packaging?

Should I offer packaging?

PLEASE DON'T CLICK ON "READ MORE" UNTIL YOU HAVE VOTED!

Thursday, January 13, 2011

Programming, lots of programming

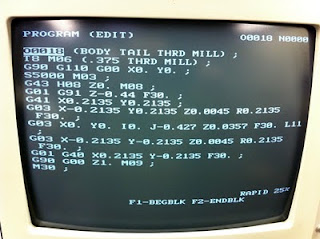

Anyway, here is what G-Code looks like. Doesn't make any sense does it?

Wednesday, January 12, 2011

New (to me) Haas VF-1 CNC Mill

So, working full time and then some (60 hrs a week) I could pump out 24 lights a month. This wasn't going to cut it, because I need time for things like writing this blog. It became apparent fairly quickly that if I was serious about making lights then I was going to need some more serious hardware.

|

| If anyone needs a rigger in the Bay Area, Curtis Roybal is the man. |

Tuesday, January 11, 2011

It all started when...

- Pack up and sell off/store all of my shop equipment...then get a real job, you know, with a desk

- Move into a smaller space and find some way for the shop to pay for more than just the rent

|

| I was horrified to find my shop almost takes up an entire semi truck. |

Monday, January 10, 2011

"What stops me from going to a "big box" and buying a flashlight for five dollars?"

The short answer: nothing.

The longer answer: if that's how you feel after trying my light...then you probably aren't one of my customers.

|

| SSC-P7 900 Lumen Prototype |

That sounds totally rude, but that's not my intent at all. I don't expect to sell a light to every person in my neighborhood.

But if you want to compare...it's 20-50 times brighter, rechargeable, cool looking, and only a few people in the world will ever own one. If you aren't into that then there probably isn't anything I can say to convince you. My selling proposition isn't "low prices, everyday." My selling proposition is "way more awesome than you have ever seen before." Can you dig it?

Sunday, January 9, 2011

Hello World...

|

| Prototype V1 |